ON STAGE, BACKSTAGE AND ...

the most important points at a glance

Visit from Austria

In the morning, we delved into the world of technology, proudly showcasing our products in the showroom and

Good vibes in Rimini

Early April, we were at MIR 2024 in Rimini. Together with our Italian partner, Alpha Concept, we presented our moving heads

30 years at JB-Lighting

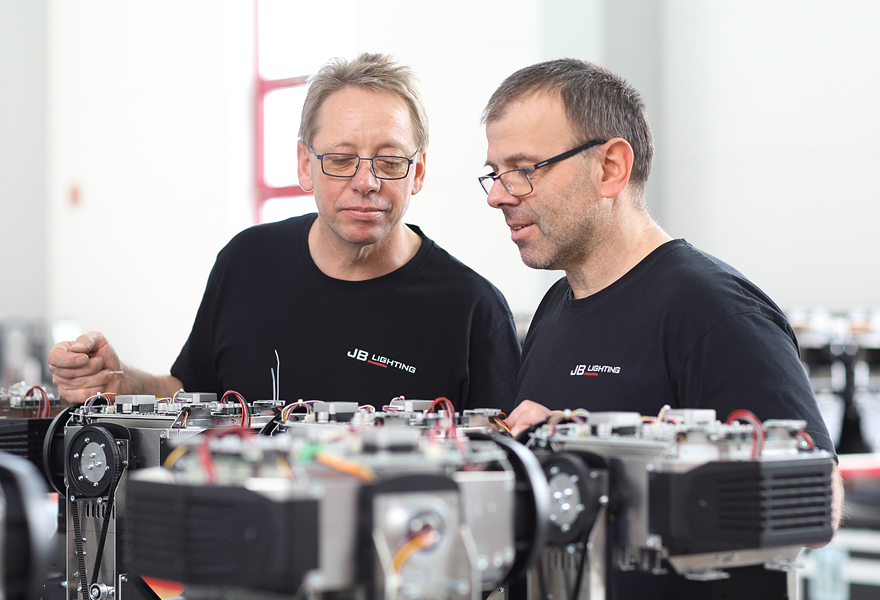

Working together

Contributing together

Thinking together

Being together

Contributing together

Thinking together

Being together

prolight + sound 2024

Fantastic days at prolight + sound 2024 are behind us. It was great to see you again.

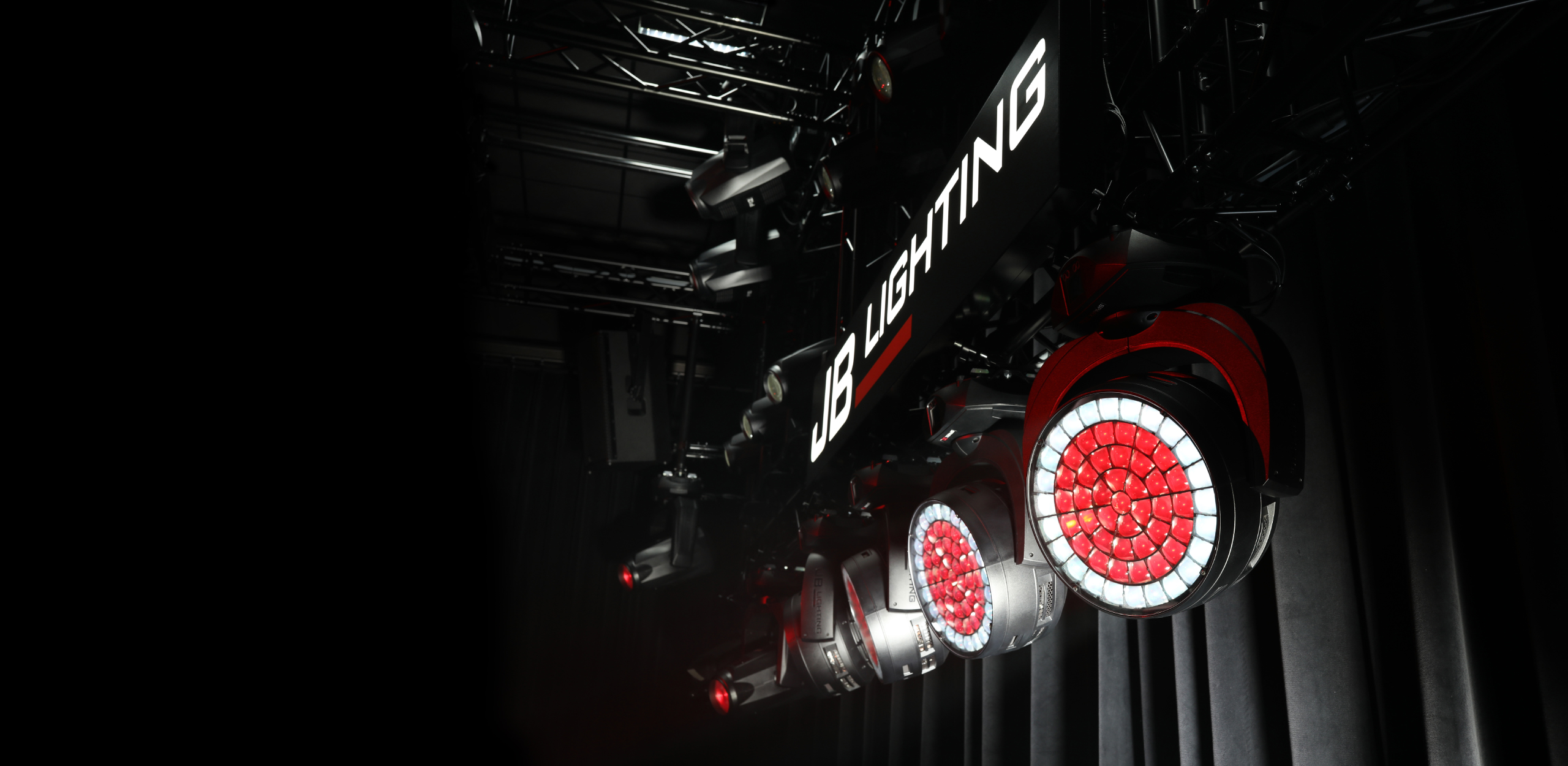

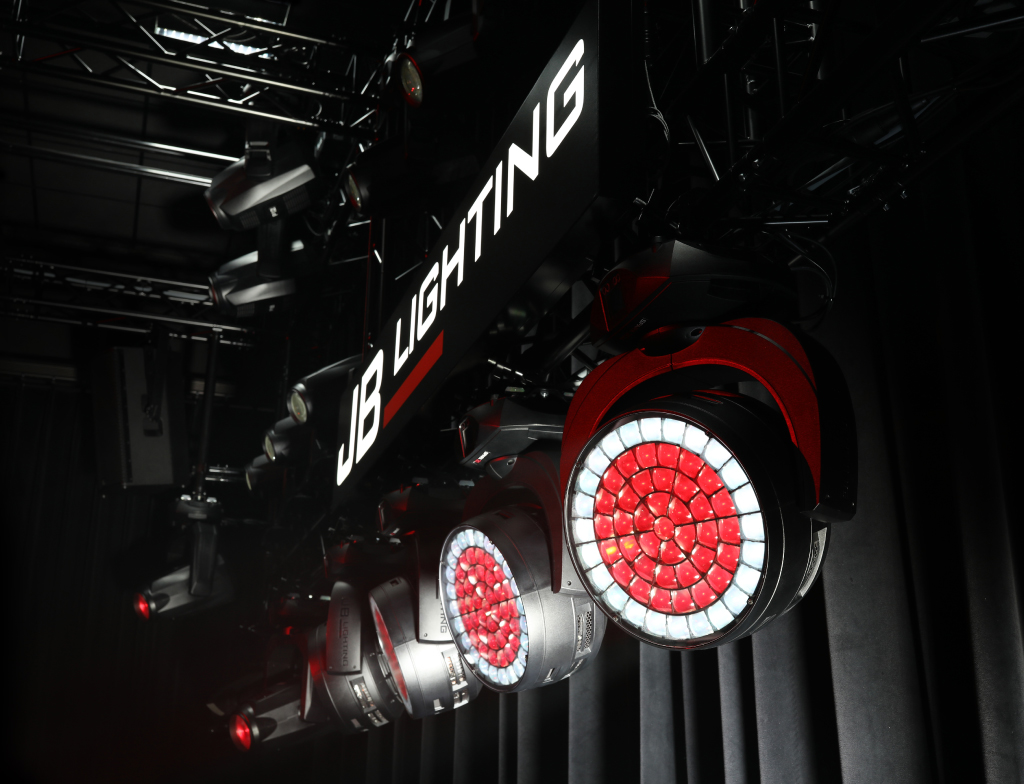

IMPRESSIVE IN EVERY RESPECT!

Light solutions at their best

High-powered moving lights from JB-Lighting – the only manufacturer of intelligent light systems to develop and make its quality products solely in Germany. Your star ensemble for professional lighting effects and stage lighting – made in Germany.

JB-LIGHTING SERVICE

Professional all-round service

We place the utmost importance on the use of high-quality, sturdy components and long-lasting, low-maintenance technologies in the development, design and production of our high-tech products.

If, despite this, you require technical support for one of our JB units, you’re at the right address with JB.

At JB-Lighting, the best possible service is part of our approach to quality – short processing times, expert advice, and rapid technical support and spare part supply make up an outstanding price/performance ratio.

If, despite this, you require technical support for one of our JB units, you’re at the right address with JB.

At JB-Lighting, the best possible service is part of our approach to quality – short processing times, expert advice, and rapid technical support and spare part supply make up an outstanding price/performance ratio.

Your service contact | |

|

Benjamin ŠimegService manager

+49 (0)7304 9617-75

simeg@jb-lighting.de |

JB-LIGHTING TEAMWORK

Experience. Vision. Passion.

JB-Lighting has been developing, designing and producing intelligent spotlights and lighting technology solutions in Blaustein near Ulm for more than 30 years, with a team of utterly skilled professionals.

JB-Lighting is also a trendsetter, distinguished many times over for innovations in LED-based moving light systems, regularly marking accomplishments and milestones in development as a premium provider.

JB-Lighting is also a trendsetter, distinguished many times over for innovations in LED-based moving light systems, regularly marking accomplishments and milestones in development as a premium provider.

JB User Network - the community portal

Who has what and how many JB products are in stock and where can I

rent them? Our User Network provides you with the answer. Simply filter by town or postcode, distance and the JB product you need and possible rental companies will be displayed immediately – lets get started!

Forgotten password?

Registration

In order to be able to use our User Network or to store your company data (My Account) and your stock of JB devices, registration with subsequent authorisation is required!

Register now